Understanding CE Automatic Wire Twisting Machines: A Guide for Electrical Manufacturers

Release time:

2025-04-28

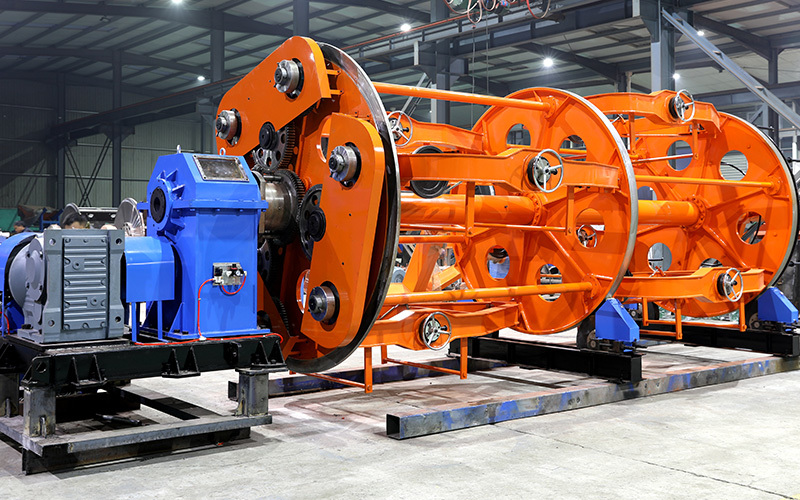

In the realm of electrical and electronic product manufacturing, the importance of efficient and reliable machinery cannot be overstated. Among the various types of machines utilized, the CE automatic wire twisting machine stands out as a critical piece of equipment in the wire processing segment. This machine is designed to automate the process of twisting wires together, creating consistent and

A CE automatic wire twisting machine operates by taking multiple strands of wire and twisting them together in a precise manner. This process not only ensures mechanical stability but also enhances electrical connectivity. The automation aspect of the machine significantly reduces human error, increases production speed, and allows for more complex wiring configurations that would be difficult to achieve manually.

One of the key advantages of using a CE automatic wire twisting machine is its ability to handle different wire sizes and types. This versatility makes it suitable for various applications, including the manufacturing of electrical cords, automotive wiring, and consumer electronics. The machine is equipped with advanced features such as adjustable twisting speeds and programmable settings, which allow manufacturers to tailor the twisting process to their specific needs.

Moreover, the incorporation of CE certification in these machines indicates compliance with European safety standards. This certification not only assures manufacturers of the machine's reliability and safety but also enhances product credibility in the international market. Investing in CE certified machinery is beneficial for manufacturers aiming to expand their market reach, as it demonstrates a commitment to quality and safety.

In terms of maintenance, CE automatic wire twisting machines require regular checks to ensure optimal performance. Keeping the machine clean and monitoring for wear and tear are essential practices that can prolong its lifespan and maintain production quality. Additionally, training operators to understand the machine's functions and capabilities can further enhance its efficiency.

When considering the acquisition of a CE automatic wire twisting machine, it's essential for manufacturers to assess their specific operational needs. Factors such as production volume, wire types, and the complexity of the products being made should influence the decision-making process. By carefully evaluating these aspects, manufacturers can select a machine that aligns with their production goals and enhances their manufacturing capabilities.

In conclusion, the CE automatic wire twisting machine is an indispensable tool for electrical and electronic product manufacturers. Its ability to deliver efficiency, consistency, and compliance with safety standards makes it a worthy investment for any manufacturing operation focused on quality and productivity. Understanding its features and benefits can empower manufacturers to make informed decisions, thereby improving their overall operational efficiency.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province